Composite Mounting Platforms (CPAD)

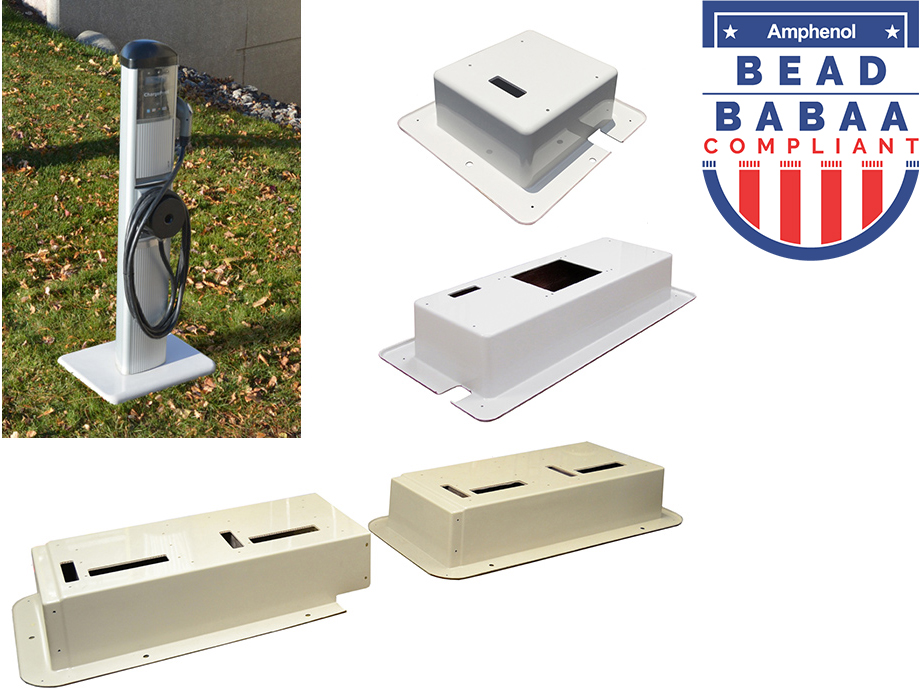

Broadband Equity Access & Deployment Program (BEAD) and Build America, Buy America Act (BABAA) compliant*

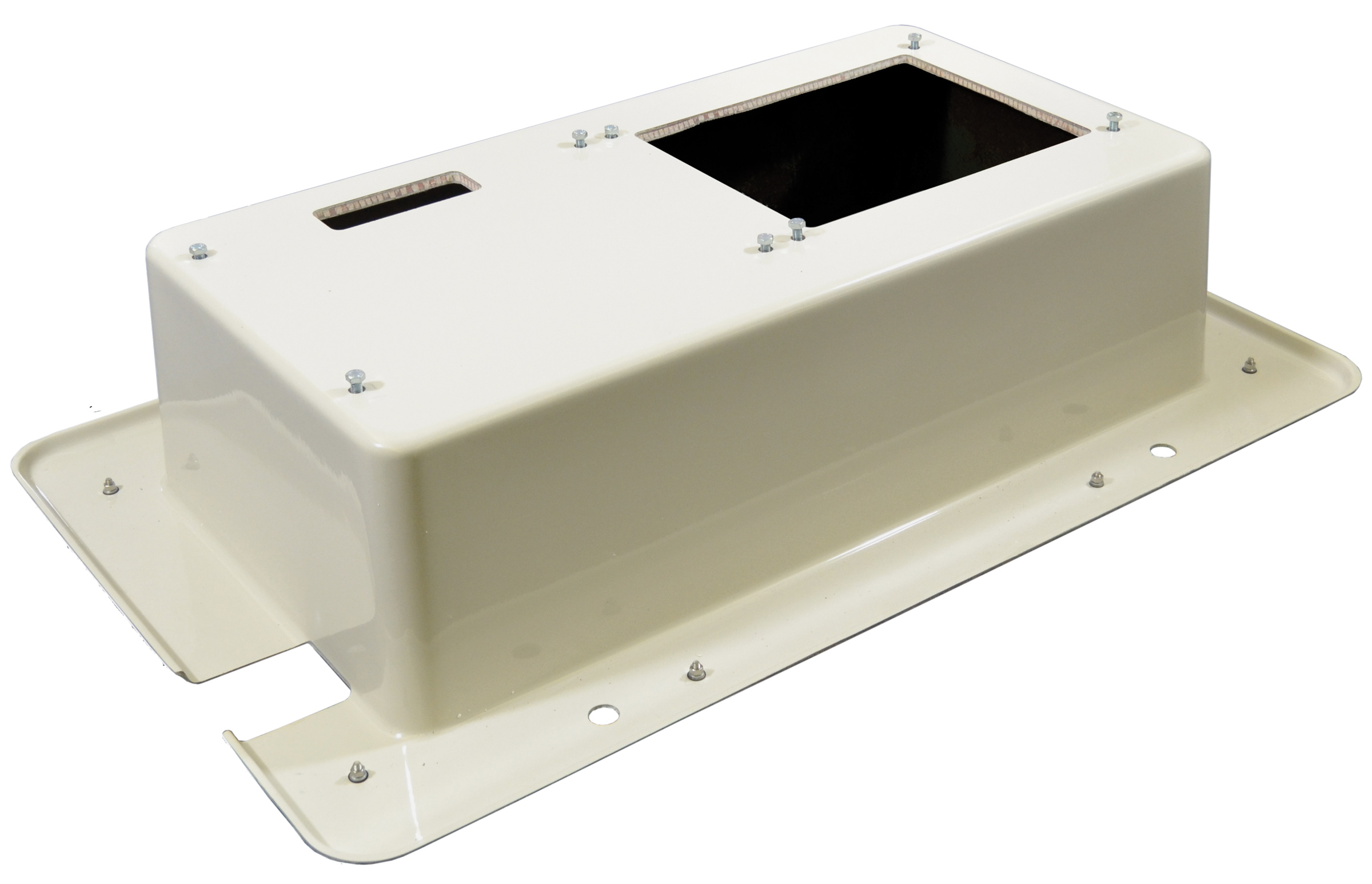

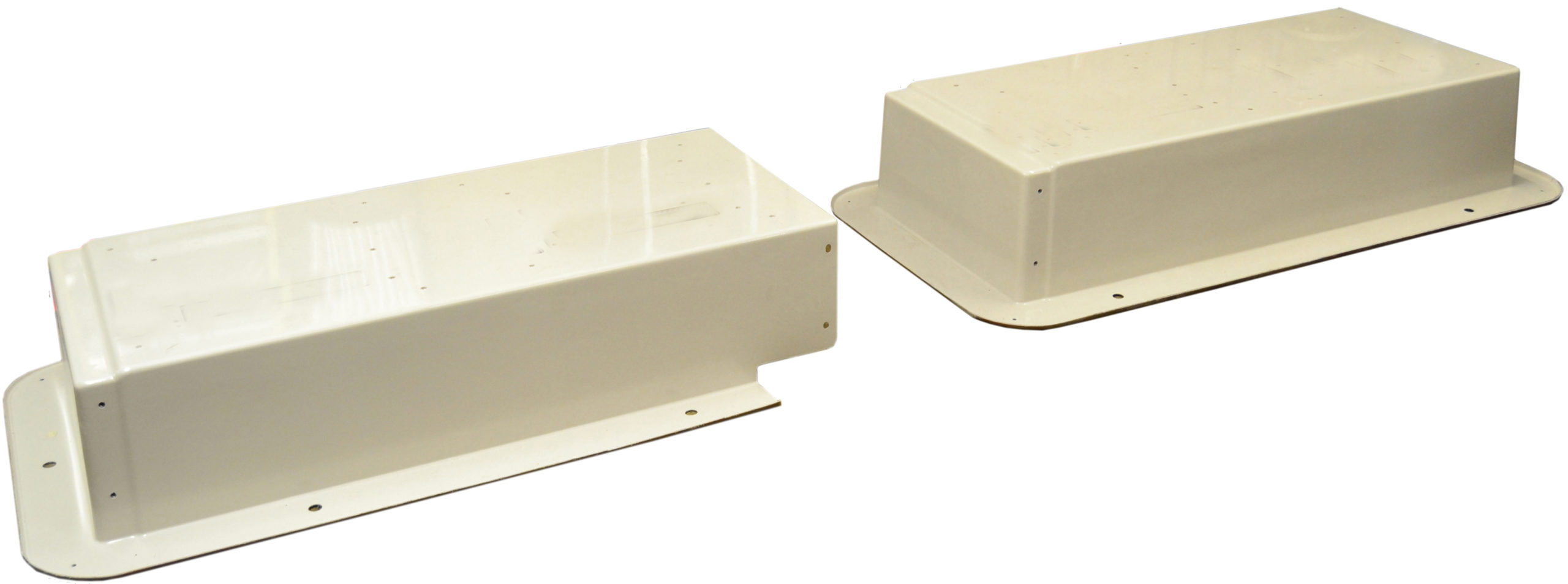

Charles Composite Pads (CPAD) are economical alternatives for poured in place and pre-cast concrete pads. They eliminate on-site work, save time, and reduce injury risk associated with handling and maneuvering heavy concrete. With today’s compressed schedules to complete builds, the CPAD solution enables rapid deployment with minimal on-site project planning and coordination. Made from advanced composite materials, CPAD are extremely durable, lightweight, and simple to install.

There are application specific pads for all Charles wireless and wireline cabinets. Charles has also developed a line of Universal CPAD compatible for mounting cabinets, generators, and pedestals from nearly any manufacturer. CPAD are available and suitable for a number of other outdoor equipment installations such as electric vehicle charging stations and kiosks with digital signage.

*Looking for BABAA-compliant products for your BEAD-funded projects? Talk to our sales representative today and learn more about our BABAA-compliant product portfolios.

Features and Benefits

Added benefit of additional storage under platform for cable slack and conduit

One-piece and modular designs available

Allows for rapid placement without heavy equipment or curing time

Enables same-day installation of pad mount enclosures and equipment

Non-conductive for improved safety

Usable on inclines of up to 15% grade

Suitable for a number of other outdoor equipment installations including wireline and wireless cabinets, generators, electric vehicle charging stations and signage kiosks

Documents and Download

Documents

Wireless Enclosure Platforms

Small Cell

A variety of CPADs have been designed to match Charles groundmount Small Cell cabinet and shroud solutions

Small Cell CPAD Solutions

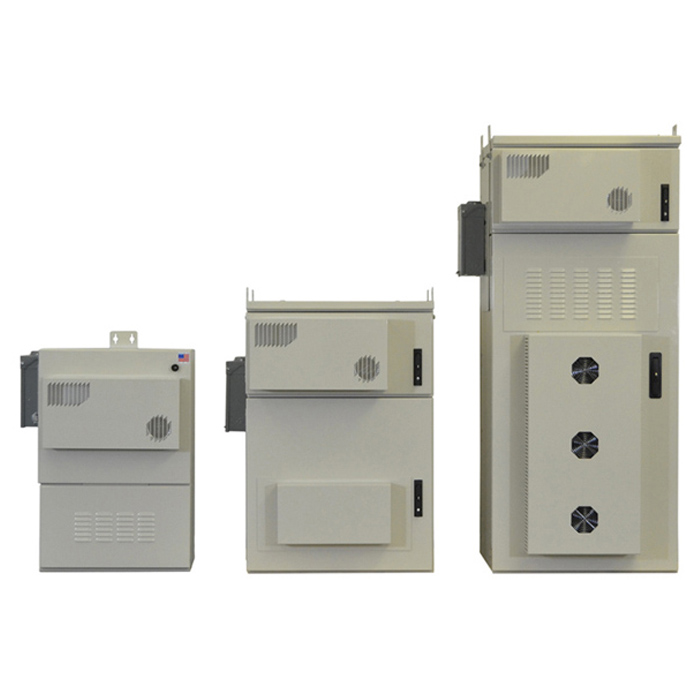

Macro Site

A modular CPAD solution has been designed which accommodates Charles Macro Site Cabinet Solutions including Site Support, Battery Backup and Equipment Cabinets. Separate CPAD solutions are available to support diesel generators from Generac, Kohler, Polar and MTU

Macro Site CPAD Solutions

Wireline Enclosure Solutions

Fiber Hub

The Integrated CPAD with 30″x48″ TRUE Split Cover Below Grade Enclosure in an all-in-one solution designed for mounting Primary Flexibility Point (PFP) cabinets with room below the pad and cover for sealed fiber splice cases and cable slack storage

Fiber Hub CPAD Solutions

Universal Applications

Ground Mount Cabinets & Generators

The Universal CPAD supports cabinets and generators from all manufacturers. The cabinet or generator’s mounting holes are used as a template, with holes being drilled for perfect placement, and then anchors installed from the top

Universal CPAD Solutions

Electric Vehicle Charging Stations

Universal CPAD designs are available for softscape installation EVC Stations, providing an economical and quick-installation alternative to concrete slabs

EVC CPAD Solutions

Whitepaper: Using Composite Mounting Pads to Rapidly and Reliably Deploy EV Charging Infrastructure Charles industries

Digital Signs & Kiosks

The Universal CPAD may also be used support digital sign and kiosk installations, providing an economical and quick installation alternative to poured concreted installations

Looking for BABAA compliant product for BEAD funded projects? Please CONTACT CHARLES for more information, including available options.

Looking for BEAD/BABAA compliant products?

If you're looking for BABAA-approved products eligible for BEAD funding, we've got you covered. Please take a moment to fill out our quick form, and we'll provide you with all the information you need on our compliant FTTH products. Your journey to enhanced connectivity starts here!